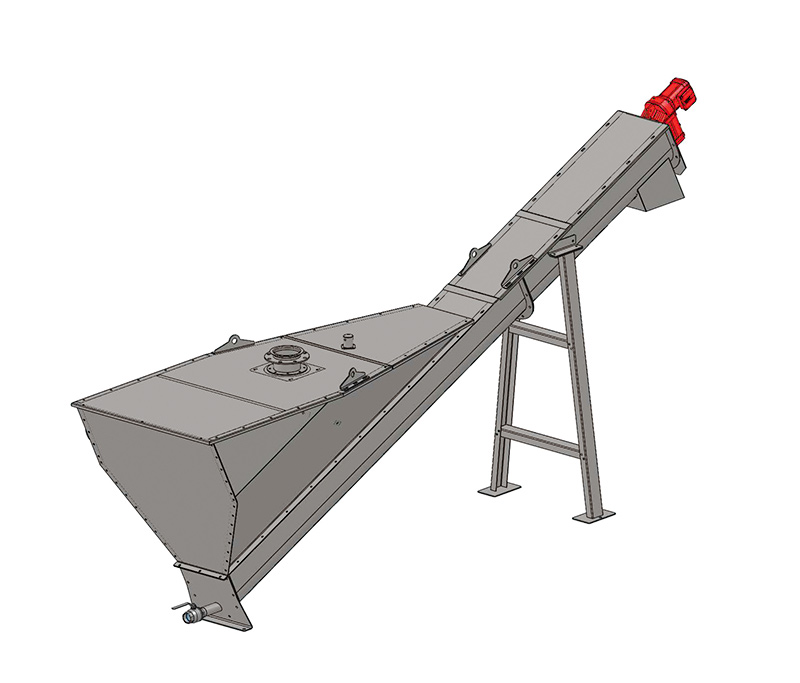

DESCRIPTION AND WORKING PRINCIPLES

Grit separators are used to remove grit from water. These separators consist of a shaftless screw conveyor provided with a big sedimentation hopper, including inlet/outlet flanged spouts. Effluent flows through the hopper, that is designed specifically to allow the sedimentation process while the grit separation takes place. The shaftless screw extracts the grits from the hopper’s bottom, while the cleaned water outflow trough the outlet spout. The water enters the hopper and the sand falls on the bottom, to then be extracted from the cochlea that, by rotating at low speed, avoiding turbulence and increases the efficiency of the process. The trough of the extraction screw is protected by a wear-resistant coating HDPE or in bars of stainless steel.

MANUFACTURING FEATURES

- Screw: high strength carbon steel or stainless steel AISI 304/316

- Structure: stainless steel AISI 304/316

- Trough Protection: HDPE liner or bolted stainless steel wearing bars in AISI 304/316.

- Grit separation: ≥ 90% for particles up to 200 μm

- Inlet Flow Rate: up to 100 m3/h.