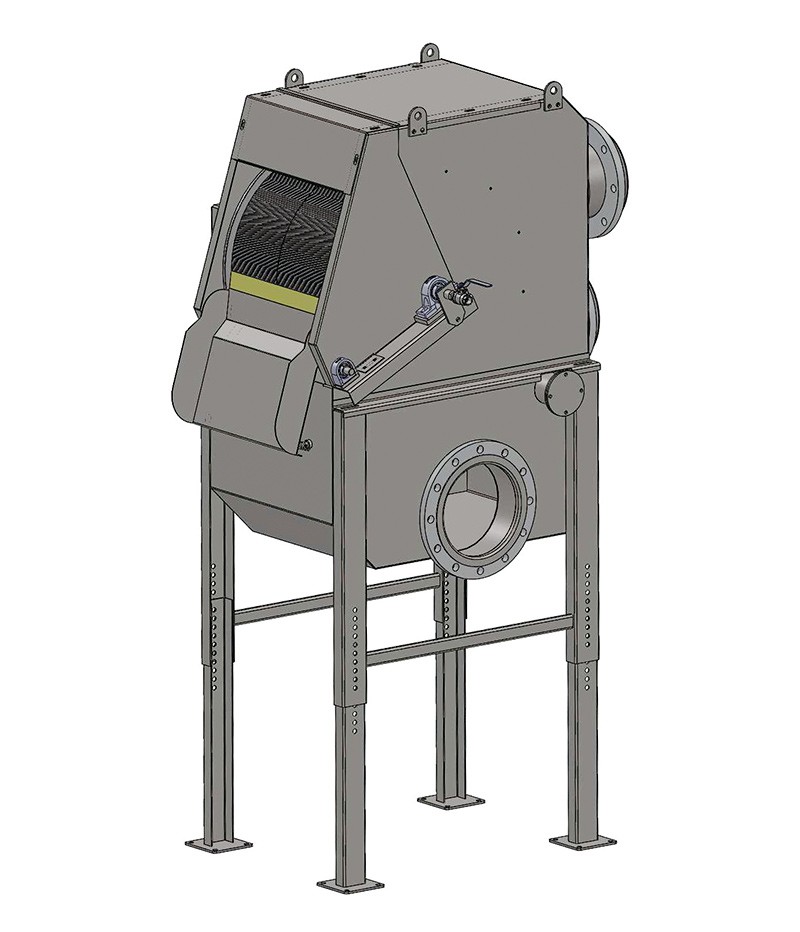

DESCRIPTION AND WORKING PRINCIPLES

X-SRD screens are used for solid/liquid separation for high flow rate and combine two operations: filtration and compacting. They feature a screen basket, perforated sheet or wedge wire, that act as a filter and rotating with the transport screw, followed by the transport section that ends with a compacting/ dewatering modulus that can be provided with a chute or a bagging system. Screenings are conveyed by a shafted screw untill the compacting/dewatering section where both the volume and the weight are reduced (up to 40%). The machine is usually placed inside a channel of suitable width, but may be placed inside a receiving tank.

MANUFACTURING FEATURES

- Screw: stainless steel AISI 304/316

- Structure: stainless steel AISI 304/316

- Length: the total length may be varied to meet the plant lay-out specifications

- Trough Protection: bolted stainless steel wearing bars

- Screen Basket: perforated sheet or wedge wire

- Screen Basket Cleaning: brushes and spray nozzles.