Separation Technology

BAUER SEPARATORS

Strong output and optimum dry matter content are the characteristics of BAUER Separators. Their long durability lead back to many years of experience, perfect technical design and the use of high-quality material. This makes us the technological leader in this field.

Based on our quality assurance system ISO9001 and constant development of all our components, Bauer manufactures products of only the highest standards.

Separation saves money

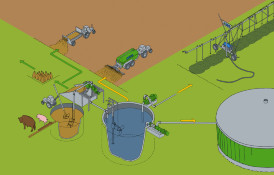

Separation stands at the forefront of liquid manure management. It is the starting point of subsequent meaningful liquid manure preparation. After separating into solid and liquid media, many useful opportunities for further processing exist. For instance, the separated solid portion is used today to produce valuable bedding material or compost. The liquid manure in turn ensures reliable growth in the fields during every growing season. It replaces chemical fertilizer to save money, lowers environmental impact and promotes animal health.

Lower costs, better animal health – BAUER.

The BAUER SEPARATOR converts manure into a valuable fertilizer

Fully-automatic separation – that means splitting up slurry into a liquid and a solid fraction – offers great advantages.

The thin slurry remaining can be distributed any time without any sophisticated homogenizing techniques.

The odorless solid fraction is easy to store without any problems

Economical use of existing resources with up-to-date technologies.

Farms with high animal concentrations are faced with great problems due to the large amounts of manure. This applies particularly to farms with a high stock per unit and area. Existing legal requirements aggravate the situation. For this reason, slurry must be treated adequately. Customary manure management systems are time-consuming, labor-intensive and can require enormous investments as well.

High economic efficiency

Slurry separation is the ideal solution for farms with a large animal population and small distribution areas. It reduces the storage capacity requirement up to 30%. Through specific use of nutrients of the liquid and solid fractions, mineral fertilizers can be saved. Extra profits are possible by selling the solids to small gardeners for example, or as a basis of compost for horticultural farms.

Separator S300

Standard Extent of Supply S300

- Auger of stainless steel

- Screen of stainless steel

- Screen sizes to choose: 0.25 / 0.50 / 0.75 / 1.00 mm

- Housing of cast iron

- Discharge flaps of stainless steel, with 2 weights

- Mounting frame of galvanized steel

- Multi-range gearmotor 2,2 kW 400 V / 50 Hz

- Inlet piece with flanged tubes 3″ (entry / overflow), ventilation 1 1/2″

- Clear phase hose connection DN 90

Standard Extent of Supply S 655

- auger of stainless steel

- screen of stainless steel

- screen sizes to choose: 0,25mm, 0,35mm, 0,5mm, 0,75mm bzw. 1,0mm

- housing and shell of cast iron

- discharge flaps of stainless steel, with 4 weights

- mounting frame in stainless steel for mounting on the ground

- multi range gearmotor with connector block 5,5 KW, 400 V/50 Hz

- inlet T-piece (entry – socket HK 108, over flow – ball HK 108)

- HD model: with heavy duty screen for applications where higher percentage of dry matter content in solids is needed.

Separator 855

- Standard Extent of Supply S 855

- Auger (long version) made of stainless steel

- 2 Screens (reinforced+HD short) of stainless steel

- Screen sizes to choose: 0,25mm, 0,35mm, 0,5mm, 0,75mm bzw. 1,0mm

- Housing of cast iron

- Extension of housing, stainless steel

- Discharge flaps of stainless steel, with 4 weights

- Mounting frame in stainless steel for mounting on the ground

- Multi range gearmotor with connector block 5,5 KW, 400 V/50 Hz

- Inlet T-piece (entry – socket HK 108, over flow – ball HK 108)

- HD model: with 7,5 kW motor and 2x heavy duty screens for applications where a higher percentage of dry matter content in the solids is needed.

Separator 855 GB

- Standard Extent of Supply S 855 GB

- Press Screw of stainless steel corediameter180mm

- 2 Screens (reinforced+HD short) of stainless steel

- Slot size 1.0mm

- housing and shell of cast iron

- extension of housing, cast iron

- discharge flaps regulated with 4 weight levers – stainless steel

- mounting frame for installing on the ground in stainless steel

- Multirange geared motor with connector block 7,5 KW, 400 V/50 Hz

- Inlet T-piece (entry – socket HK 108, over flow – ball HK 108)