DESCRIPTION

Pressure filters are used in those cases where solid substances have to be mechanically filtered out of water. These filters help improve the final quality of the effluent after chemical-biological treatment of the waste water, or can complement the process of clarifying surface water for drinking or for industrial use. They remove the suspended solids and, therefore, the phosphorous and BOD associated with these, and eliminate turbidity, unpleasant odours and flavour, and metals such as iron and manganese.

MANUFACTURING FEATURES AND WORKING PRINCIPLES

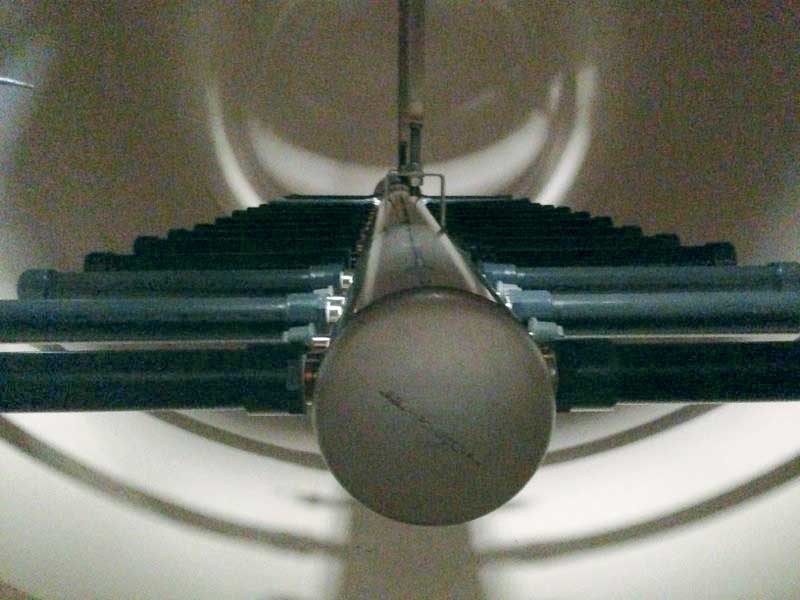

The filter consists of a cylindrical tank made of steel, with three main sections. The water to be filtered flows through a pipe into the filtration chamber where it percolates through the quartz sand or active carbons in the filter bed. The water then flows through plastic nozzles in the collection chamber into the area below and through the outlet pipe for subsequent use. The backwash process, where a water/air mixture is ejected at high pressure from the base of the filter, occurs automatically at pre-configured times.

The frequency of the backwash process can be programmed according to the manometers at filter inlet and outlet which indicate the progressive load loss due to clogging of the filter bed. The plastic nozzles ensure uniform draining of the filtered water as well as uniform distribution of the backwash air/water mixture.

A remote control can be used to automate the cycle.