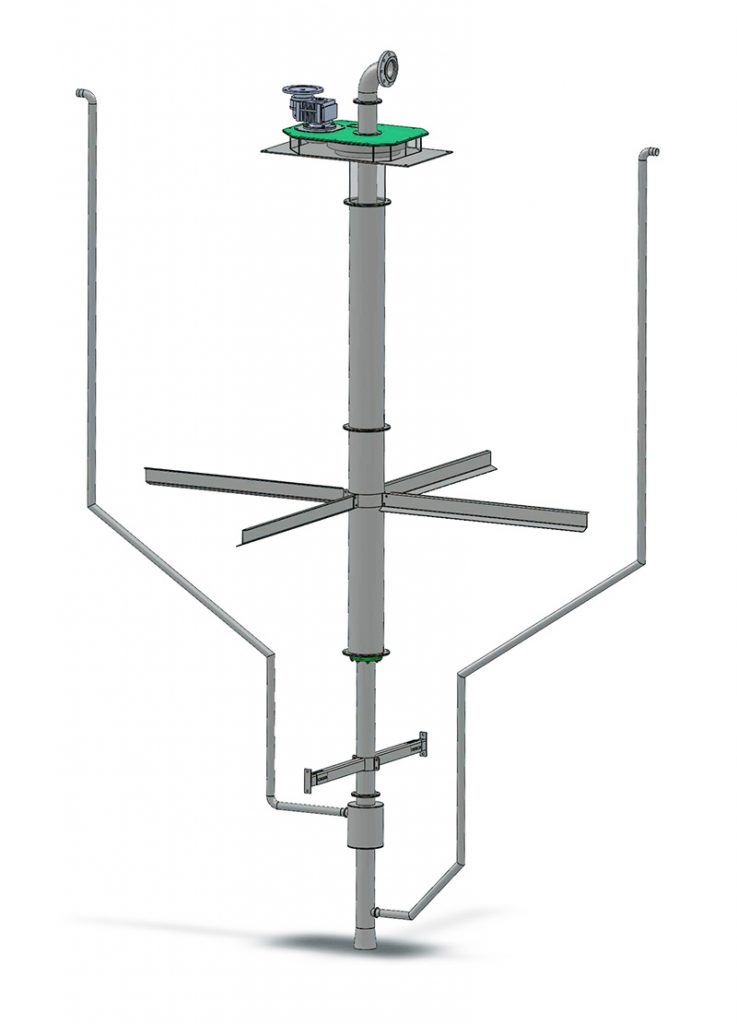

DESCRIPTION AND WORKING PRINCIPLES

The grit separator and washer is used for separating sand form the organic materials. Once in the tank, the water is stirred by paddles, so the organic components are separated from the sand. Organic components stay in suspension, till they escape out from the tank. The sand, due to its specific gravity, gets down to the conic bottom, then is extracted by an air-lift. The paddles with central shaft run by a gearmotor, endless-screw or epicycloidal-gears type.