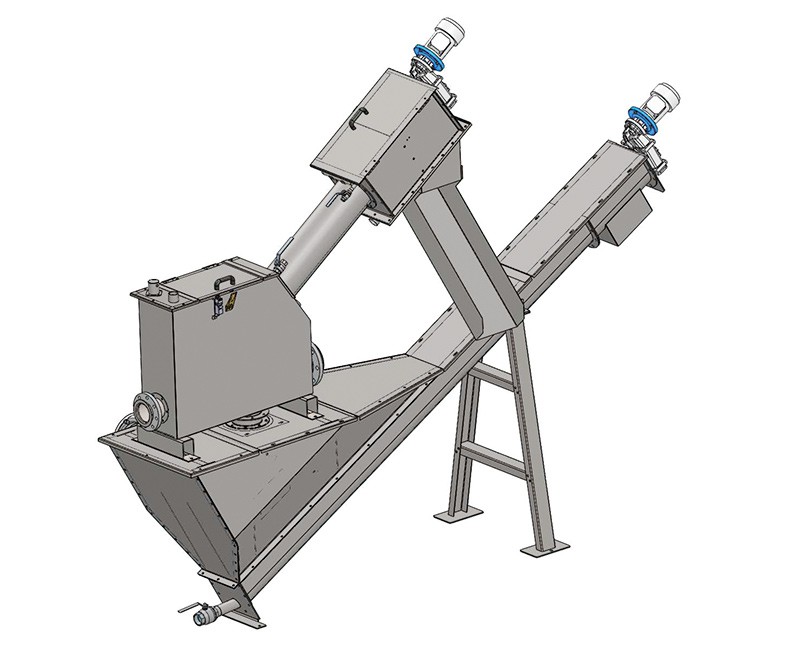

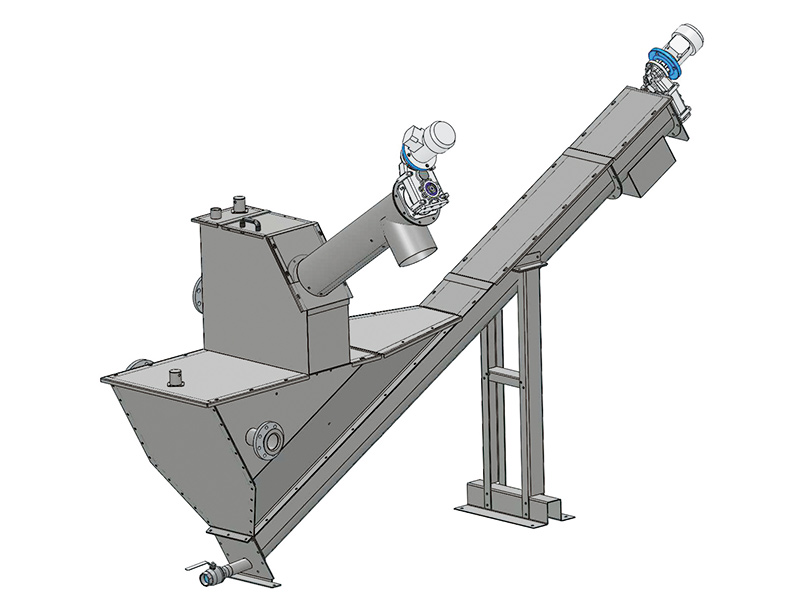

COMBINED UNIT WITH DEGREASED SYSTEM

The combined unit with degreasing system model SET 3 make a first screening with a screw screen placed on the top of the machine; the solids with dimensions major to the mesh are trapped. Thanks to a series of brushes mounted on the screw are rimoved the solids and are washed and compacted before the discharge. haks also to high pressure nozzles the screen remain without solids always. The water and the solids passed trought the screen are collected in a rectangular tank, where a blower create a whirling motion dividing the water form grit, grease and organic material; this last two remain on the surface of the water, while the grit decants on the bottom for the major specific weight where met a bottom screw that collect in a little tank the solids and an other screw lift up the solids bringing it at the external of the machine. The grease removal system is make by the whirling motion create by blower that push the grease on the opposite site of the blower where overflow in a appropriate channel; a nozzle with high pressure water bring out of the machines the grease. The clean water overflows out of the machine throught an appropriate hopper.