Agitators

Powerful- compact- user friendly

Properly stirred slurry guarantees uniform distribution of nutrients, that is to say optimum growth and increased yields. Optimum homogenisation of fluid mediums:

agriculture

biogas plants

sewage plants

industrial areas

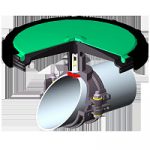

Optimum structural form – high-quality materials

A special design with the motor and propeller shaft lying on the same axis provides high efficiency. An ingenious oil-distribution system ensures optimal lubrication of the mixer at any angle.

enormous mixing capability

high efficiency

for all pit sizes

simple installation

Robust planetary reduction gearbox

Bauer mixers have a fluid, elegant and slim structural form thanks to the planetary gearbox. In combination with the large mixer blade and special stirring edges a high degree of efficiency is achieved.

enormous stirring force

high degree of efficiency

for all pit designs

easy installation